Magnet Store South Africa

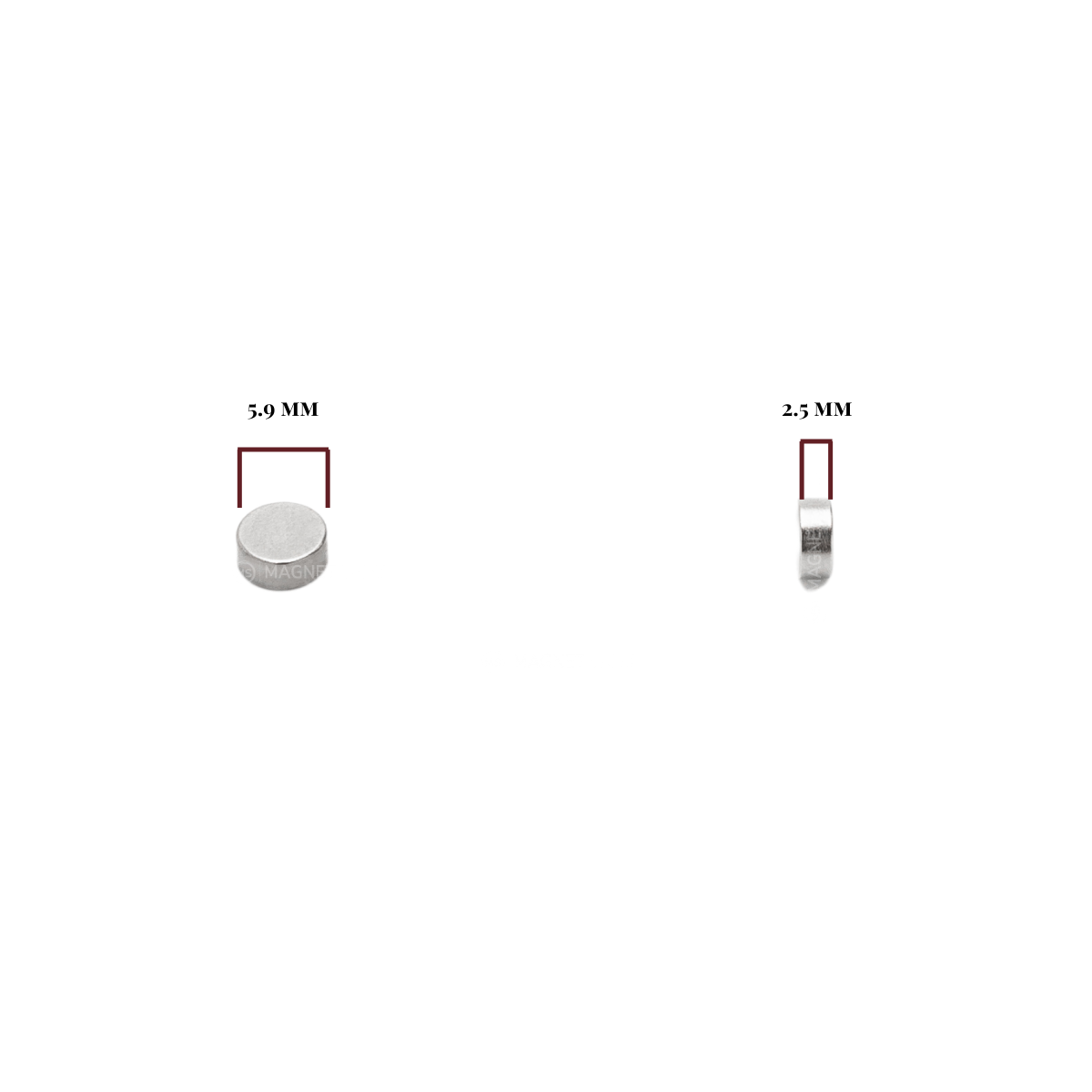

5.9x2.5mm/Diametrically N35SH Ni Neodymium Disc

5.9x2.5mm/Diametrically N35SH Ni Neodymium Disc

Couldn't load pickup availability

PRODUCT SPECIFICATIONS:

|

Material: |

Neodymium Magnets (NdFeB) |

Grading: |

N35SH |

|

Dimensions: |

5.9mm diameter x 2.5mm thick. |

Tolerance: |

+/- 0.1 |

|

Shape: |

Disc / Round |

Pulling Force: |

598g |

|

QTY: |

01 Pcs |

Colour: |

Silver |

|

Coating: |

Ni-Cu-Ni (Nickel) |

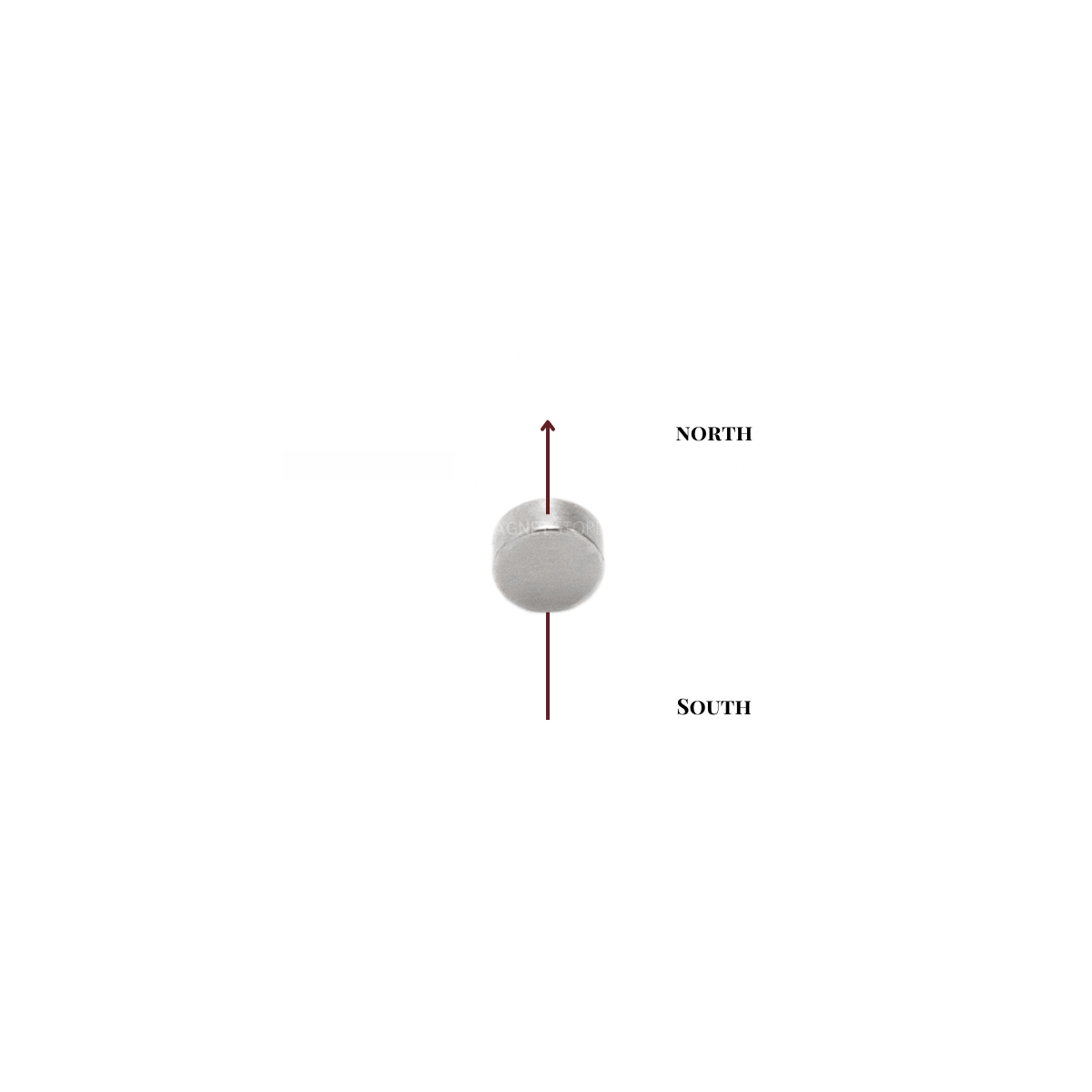

Direction of Magnetism: |

Through the diameter. |

|

Maximum temperature: |

N35SH grading magnets can work in an environment with a maximum operating temperature of 120°C. |

|

|

Image: Direction of magnetism

________________________________________

About Diametrically N35SH Ni Neodymium Disc

Neodymium Disc Diametrically N35SH Ni Magnets are high-performance magnets known for their strength and durability. Comprising an alloy of neodymium, iron, and boron, these magnets are characterized by their N35SH grade, indicating a high maximum operating temperature of up to 120°C, making them suitable for demanding environments. The nickel coating provides a sleek, corrosion-resistant finish, enhancing their longevity. These magnets are magnetized diametrically, meaning the magnetic poles are on the sides of the disc, which is ideal for specific applications requiring unique magnetic field orientations.

________________________________________

Pros:

- High Magnetic Strength: The N35SH grade offers a strong magnetic field, making these magnets suitable for heavy-duty applications.

- Heat Resistance: Can withstand temperatures up to 150°C, making them suitable for high-temperature environments.

- Durable Coating: The nickel coating provides excellent corrosion resistance and enhances the magnet's durability.

- Versatile Magnetization: Diametrically magnetized, which is beneficial for applications needing a side-oriented magnetic field.

- Compact and Efficient: Offers a powerful magnetic field in a compact size, allowing for efficient design solutions.

________________________________________

Applications of Neodymium Disc Diametrically N35SH Ni Magnets:

Industrial Uses:

- Motors and Generators: Essential for high-performance motors and generators requiring strong magnetic fields and high-temperature resistance.

- Magnetic Couplings: Used in applications where a magnetic coupling with heat resistance is needed.

Electronics:

- Sensors and Actuators: Ideal for precision sensors and actuators operating in high-temperature environments.

- Audio Equipment: Used in high-quality audio devices where a specific magnetic orientation and heat resistance are beneficial.

Healthcare:

- Medical Devices: Incorporated into medical devices requiring reliable and strong magnetic fields, even at elevated temperatures.

- MRI Machines: These are useful in MRI systems that benefit from their unique magnetic properties.

Automotive:

- Electric Vehicles: Used in electric vehicle motors and regenerative braking systems where high performance and heat resistance are critical.

- Sensors: These are employed in various automotive sensors that need precise and durable magnetic fields.

Research and Development:

- Prototyping: Valuable in the R&D of new technologies requiring robust and reliable magnets with specific field orientations.

- Laboratory Equipment: Used in specialized laboratory equipment and experiments.

________________________________________

Cons:

- Brittleness: Neodymium magnets are inherently brittle and can chip or break if subjected to stress or impact.

- Safety Concerns: The strong magnetic field can cause injury if not handled with care, as the magnets can snap together forcefully.

- Corrosion Sensitivity: Despite the nickel coating, if the coating is damaged, the underlying material is susceptible to corrosion.

- Cost: High-performance magnets like the N35SH grade can be more expensive compared to lower-grade magnets.

- Temperature Limits: While they withstand higher temperatures than standard neodymium magnets, extremely high temperatures beyond their rating can cause loss of magnetism.

________________________________________

Disclaimer:

Images are for display purposes only and are not to scale. Magnets are sold per unit unless otherwise specified. Magnet Store is not responsible for any damage or injuries caused by using our products. Please read the safety and care guide.

________________________________________

Looking for custom sizing, coating, grading or bulk orders?

Please contact us at 0218513913 or info@magnetstore.co.za. Please note that only small quantities of the stock are loaded on the website. For higher quantities please contact us